Along with owning a fuel-injected motorcycle comes rapid cold-weather starts, as the bike’s fuel mapping takes into account ambient temperature and other environmental factors. Carbureted engines have lacked this auto-adjusting ability, even with the advent of electric chokes. And with these nice, smooth cold weather starts – I don’t ever want to stop riding my motorcycle!

So I recently purchased Gerbing heated jacket liner. You can buy a controller from Gerbing for ~100 bucks. But I wanted to do something a little more DIY. If you did this right, you could build your own heattroller (as they’re called) for around ~15 bucks (555 timer, MOSFET, resistors/capacitors, wiring, but more on my build).

Essentially, we need a way to switch the jacket on and off in varying degrees, depending on how hot we want the jacket. Why not use a variable resistor, you say? Stay tuned for a lesson on resistance and power. Switching something on and off is much more efficient.

Enter PWM, or Pulse Width Modulation. Some may have heard of this technology to dim LEDs, vary the speed of electric motors, or control servos in RC applications. Essentially, a square wave is generated. If you don’t know what a square wave looks like, see the Wiki page. This square wave can be generated at any frequency. Now, if the square wave spends half it’s time at max amplitude and the other half at zero potential, the duty cycle is 50%. The longer the square wave is at max amplitude, the higher the duty cycle. So that’s how we’ll control the on-off action of the jacket current – by increasing or decreasing the duty cycle.

Choosing a frequency, however is interesting. For a heated jacket, which has a lot of ‘thermal inertia’ or what I like to call it–in that it doesn’t heat up or cool down super quickly (Gerbing says it takes 4 seconds to reach max temperature) our frequency for the PWM can be fairly low. I’m using 1 Hz. Other devices, like LEDs, need to be driven at a much higher frequency because they don’t have any ‘inertia’ (not super sure what word to use here). Why make it low? Our later discussion of MOSFETs – switching losses. Read about it here.

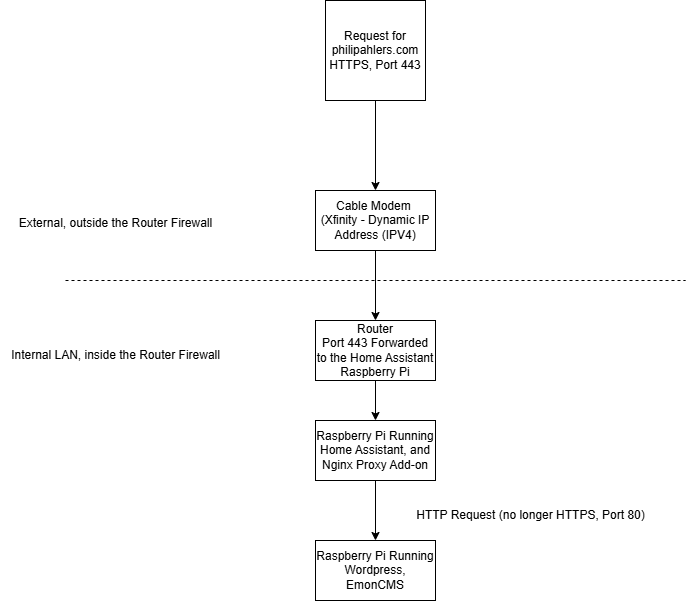

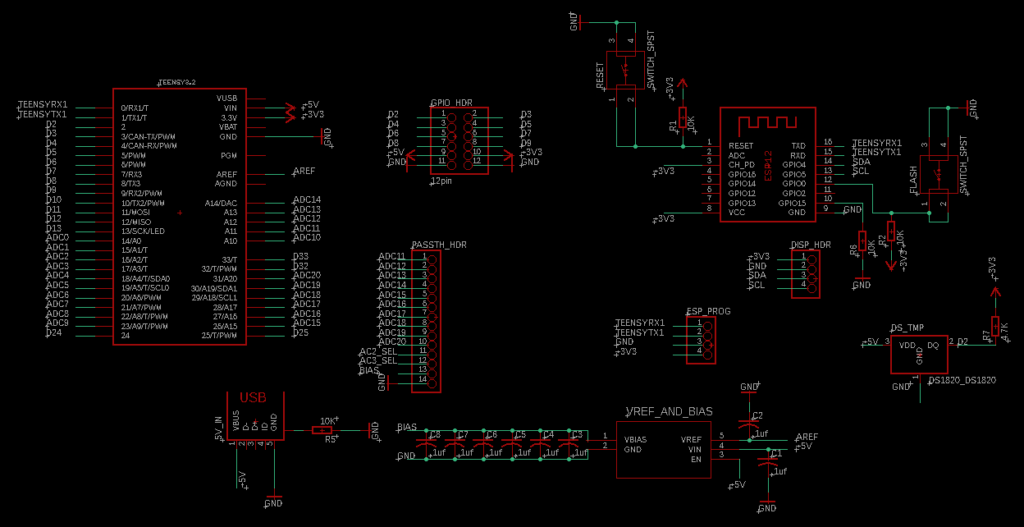

But we have another problem – what can I generate the PWM signal with? A 555-timer can be used as an astable oscillator that generates a PWM signal, with the same amplitude of what the 555 timer is powered with. But a 555 timer can only sink about 200ma of current. The Gerbing heated jacket liner is rated at 12v and 6.9A. So we need a sort of relay, or switch to do the actual on-off, and a PWM signal source.

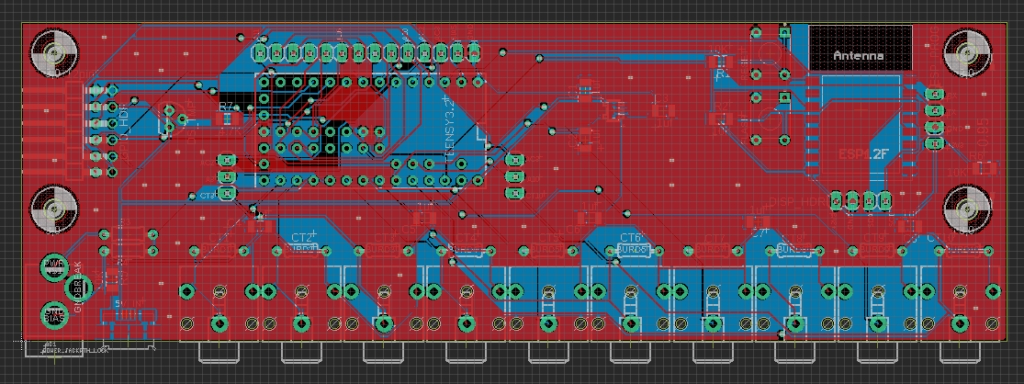

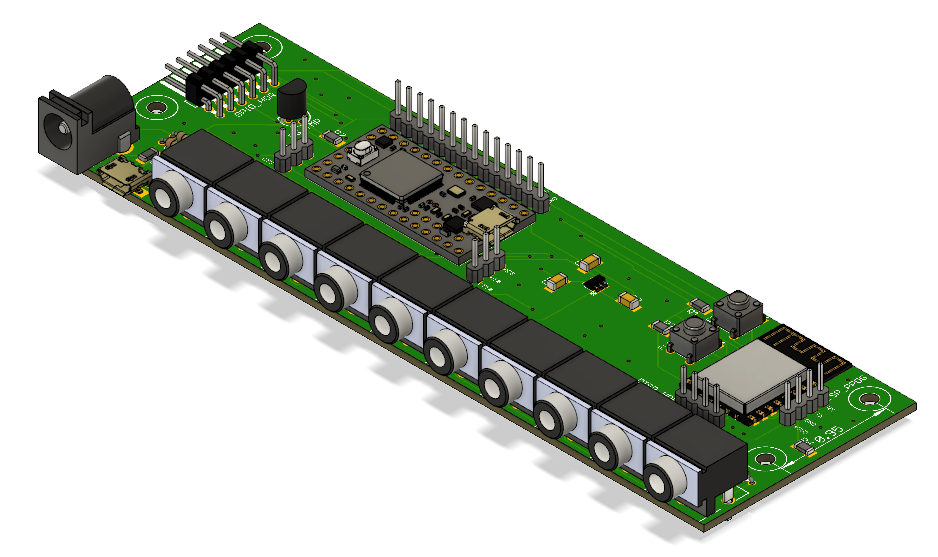

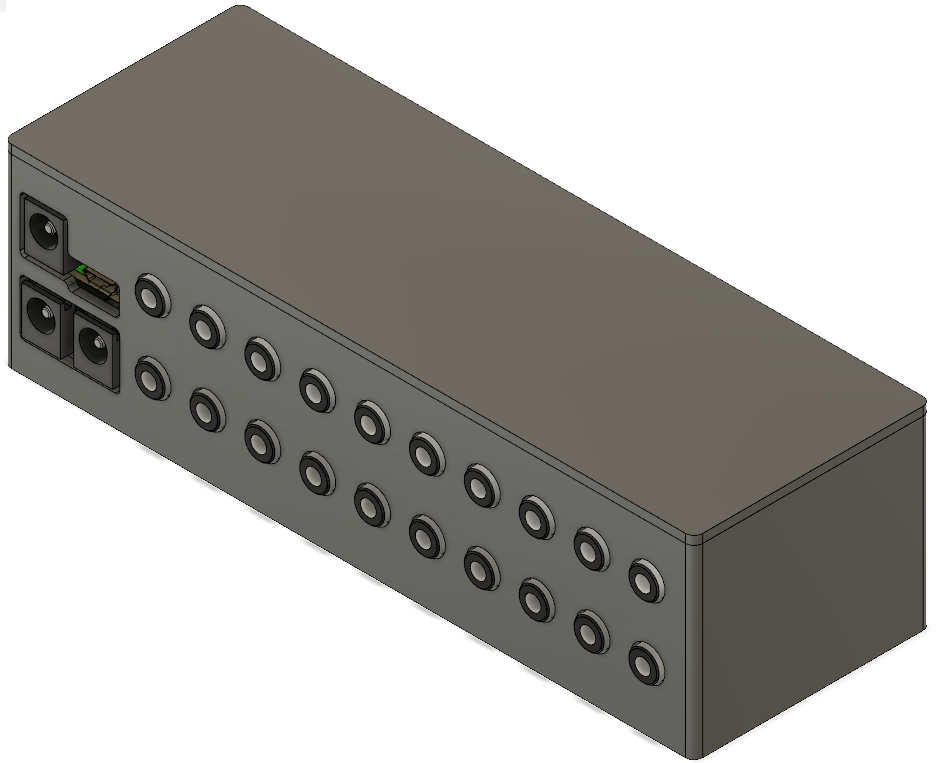

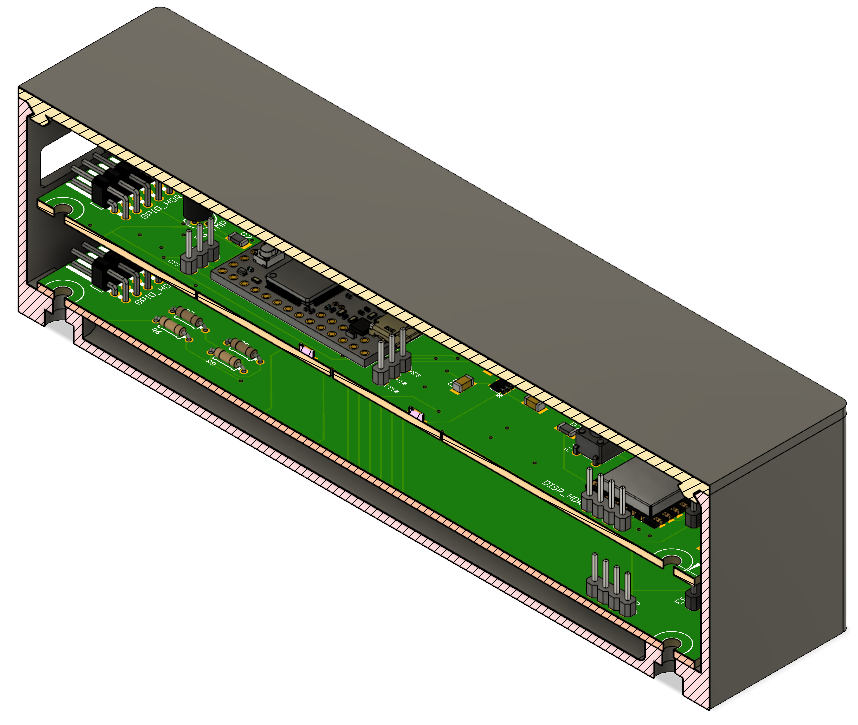

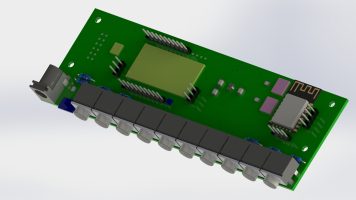

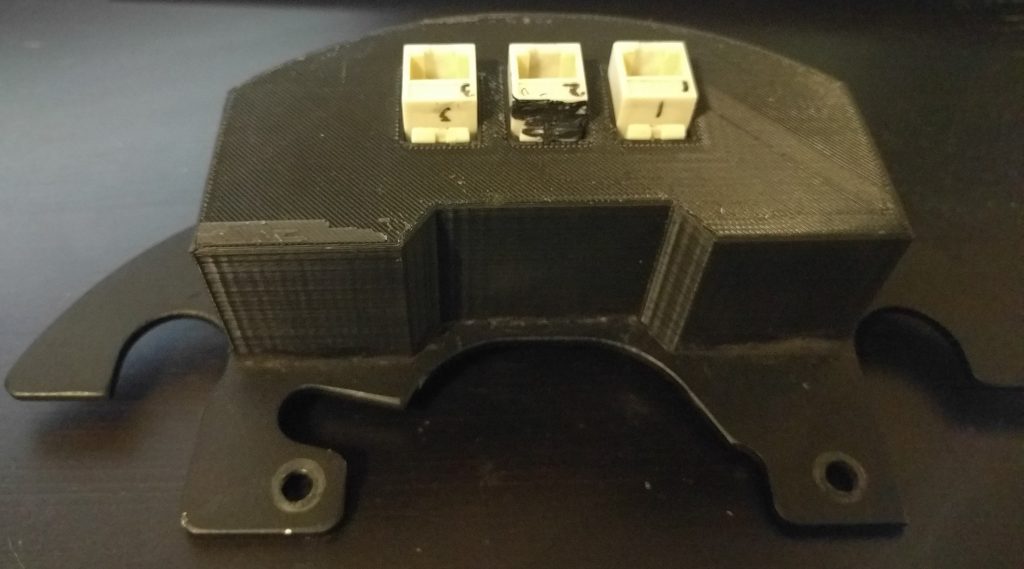

For my motorcycle, I’m attempting to build a trip computer / recorder out of a Raspberry Pi. The Raspberry Pi has GPIO pins which can be used to generate a PWM signal at any frequency or duty cycle. I won’t have to fabricate a 555 circuit! But we still will need a high-current switch. A transistor, MOSFET, or even a relay could work at these slow PWM frequencies. I wanted a solid state option, so I looked around for a MOSFET.

Laying around in my electronics bin, I had a few of these: BUZ91A. Protip: don’t ever buy these. I tried to use one, and it promptly got so hot it nearly destroyed itself. Why? Take a look at the datasheet – the Rds(on) is .9 ohms! That’s a lot. And we know that

P = V * I and V = I * R

Thus,

P = I * R * I

P = I2 * R

What does this mean? Our jacket drawing 6.9 Amps would mean the MOSFET would have to dissipate nearly 43 Watts. Not what you would call efficient or safe. That would take a fairly large heatsink. So after some looking around, I decided to purchase a few of these. The Rds(on) is only .028 ohms. Now, the MOSFET only should need to dissipate less than 1.4 Watts. That’s a bit of an improvement, I’d say. It probably won’t even need a heatsink with that load on it – especially since heated jackets are only used when the ambient temperature is <50degF.

For more info, you can read the Wiki page on PWM.

Or read up on some Ohms law (this site was awesome in college)!